A Cracking Good Visit to Stiebrs Farms

- by Maggie Kraft

As Bon Appétit Fellow Caroline Ferguson and I zipped ourselves into full-body white suits, donned hairnets, and slipped elasticized shoe covers over our sneakers, we were filled with excitement about checking out the egg production at Stiebrs Farm, a few hours south of Seattle.

Fellow Caroline Ferguson and I suited up for our tour

A family-run outfit started by Latvian immigrants Jan and Zelma Stiebrs, the farm provides Bon Appétit at Seattle University, Cornish College, Gates Foundation, Nordstrom, Saint Martin’s University, Starbucks, and several others with all of its precracked (liquid) eggs, which is quite unusual — most are supplied through a national companywide contract with a much larger vendor (also Certified Humane and cage free).

We started our visit in the liquid egg facility, a sterile area with white walls and gleaming stainless-steel equipment. Yany Stiebrs, the founders’ grandson, walked us through the process of cracking, homogenizing, and packaging the eggs. A USDA inspector works on site each day to ensure that everything is clean and sanitary. As eggs are checked at the grading plant, any considered too big or too small for cartons are sent to the liquid facility to be put to use.

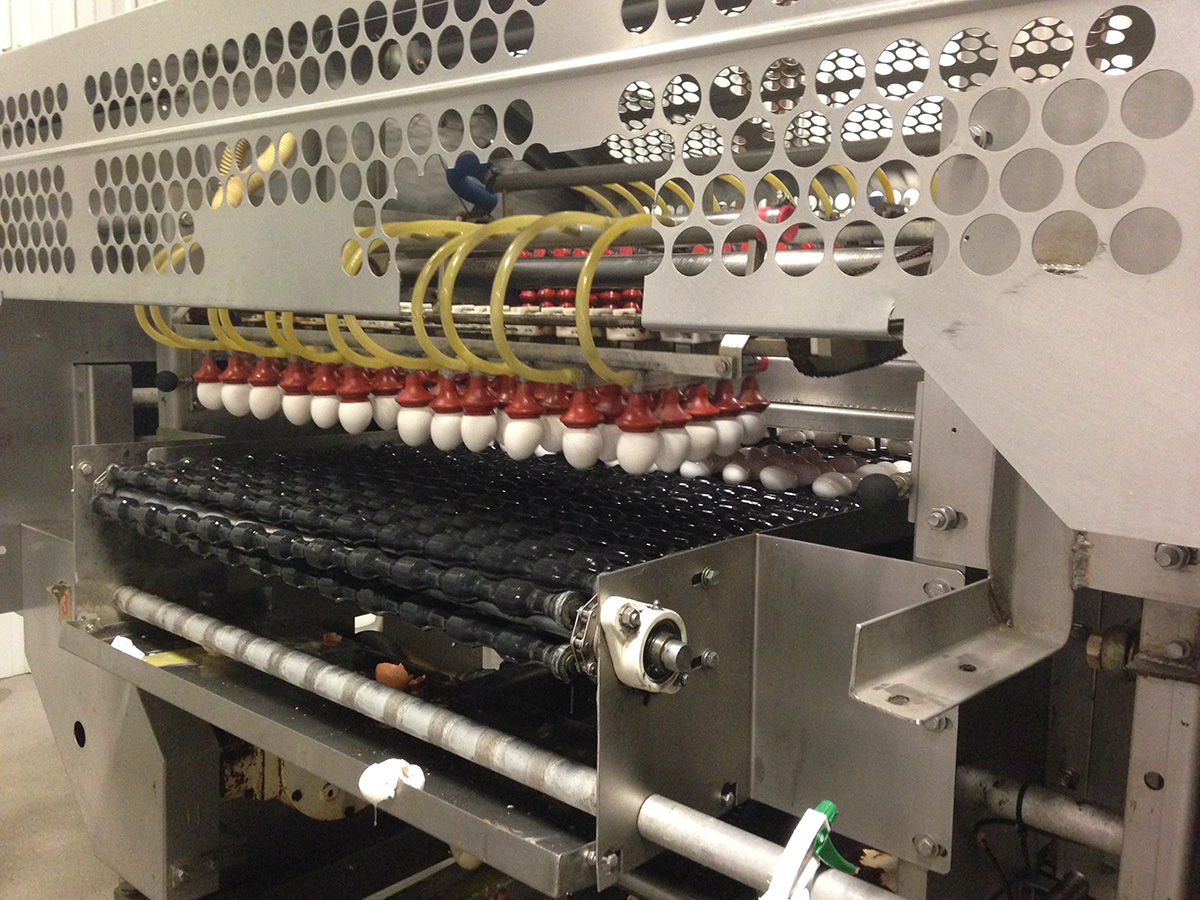

As we watched the eggs go through the process of being washed, candled (checked for blood spots in the whites or other defects), and cracked, we were amazed that it all took under a minute. We also got to see the eggs being packaged into bags, a process that took just three seconds per 30-pound bag! The packaging room’s negative air pressure keeps bacteria out before the bags are sealed.

Technology to increase efficiency and optimize sanitation was in use all over the farm, including in the chicken barns. Stiebrs raises about 750,000 chickens in multiple barns spread over roughly 1,000 acres. They raise a mix of breeds including white Leghorns and Rhode Island Browns. Some are fed conventional feed, while others are fed Certified Organic feed that’s milled on site.

Inside the egg-washing, candling, and packaging facility

Stiebrs was the first egg producer in Washington state to be Certified Humane by Humane Farm Animal Care (HFAC). We learned more about what that means in practice when Yany took us into one of the barns. In a barn housing about 17,000 chickens, the animals clucked, perched, and scratched in the dirt. When a farm is Certified Humane, part of that certification process is ensuring that animals can act out natural behaviors such as these. And while it’s required for there to be particles on the floor for the chickens to scratch in, the barn was otherwise incredibly sanitary. Yany explained that low powered fans dry the birds’ manure, which is removed via conveyor belt or by workers.

The barns are temperature- and light-controlled, too. Lights turn on and off each morning and evening to mimic the pattern of the sun, a process that helps the hens maintain natural behaviors. According to HFAC, hens often lay eggs in the morning and dust-bathe in the later afternoon. Each day, the Stiebrs’ farm managers do a walk-through to check for sick hens and “floor eggs” — those laid outside the nest. When the flocks range outside, the hens also need to be herded back inside each night.

The Stiebrs family is deeply involved in all facets of their operation, and their commitment to maintaining happy and healthy hens was clear. Their values — raising healthy animals humanely — falls squarely in line with Bon Appétit’s values and commitments. It was great for us to see firsthand the Certified Humane standard being met, and we were incredibly proud to be part of a company that supports a producer like Stiebrs.